DIGI-WELD

DIGI-WELD Checks, Fixes and Optimises your Welds.

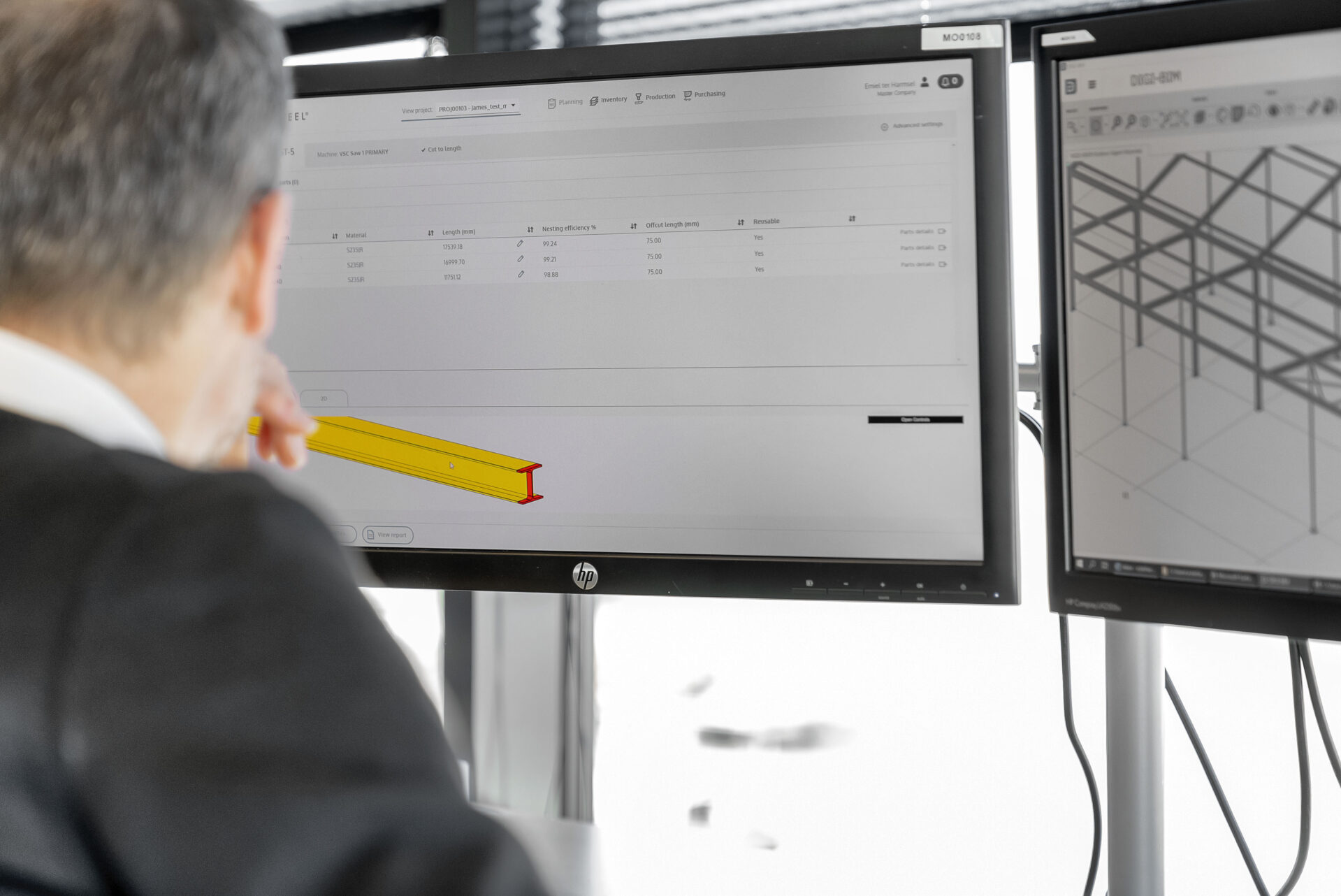

Fully integrated within DIGI-BIM, our DIGI-WELD tool gives you an accurate 3D visualisation of your project assemblies and welds. DIGI-WELD automatically flags up potential issues, giving you the chance to fix and optimise your project.

DIGI-WELD not only saves you the time, hassle and cost of potential errors in production; it also enables you to optimise welds to suit your specific machines and workflows.

Some key DIGI-WELD benefits include:

- Remap

- Check and fix tools

- Manual intervention

- Voortman Integration

DIGI-WELD BENEFITS

Remap

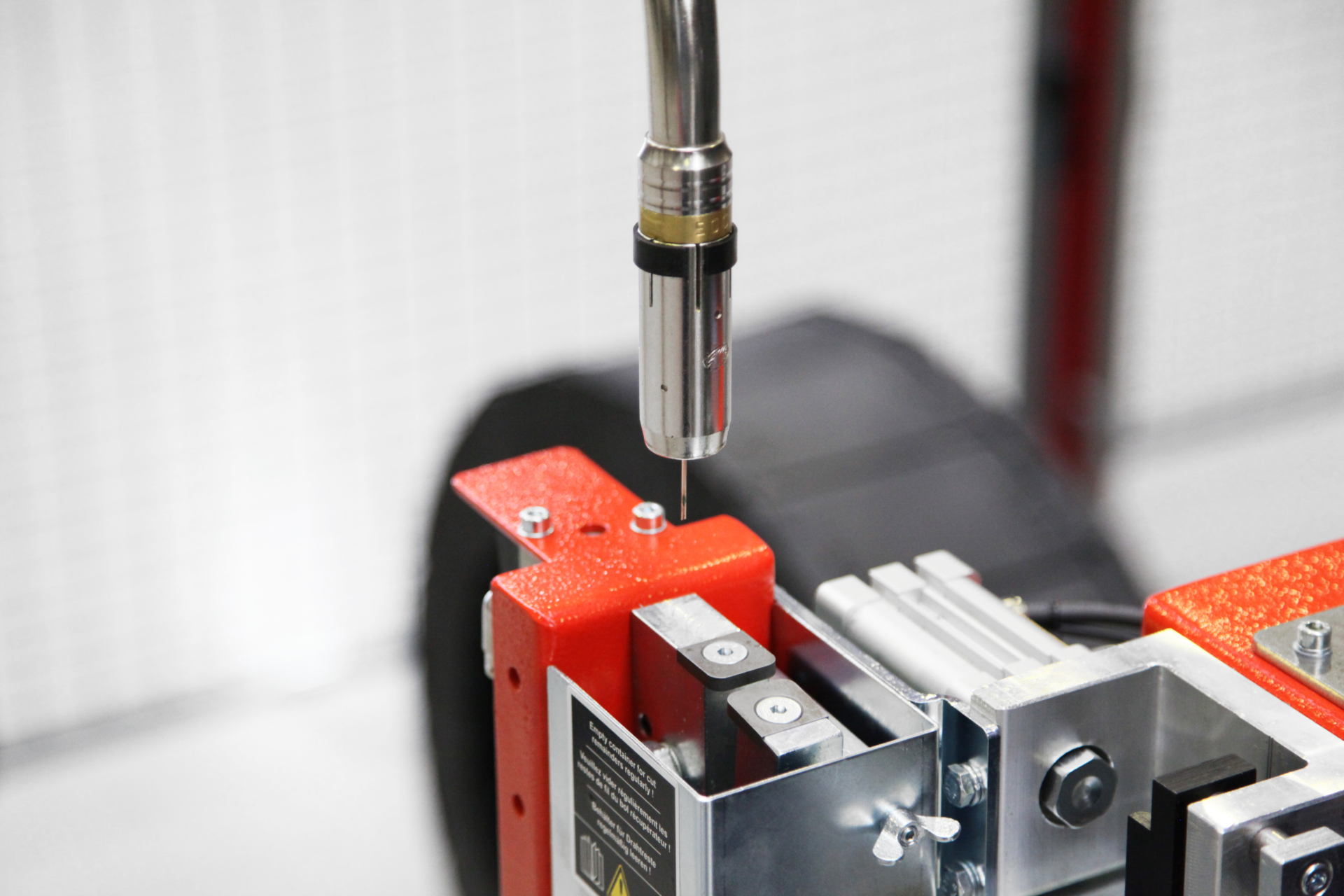

DIGI-WELD starts with the remap process, which involves defining the true weld patharound all contours of the adjoining parts.

Check and fix tools

Check and fix tools check the welds present to ensure they are both suitable and producible. The tools are able to correct a wide range of errors, including:

|

|

|

|

|

|

|

Manual intervention

Assemblies with no welds can be manually updated with intuitive tools, to allow fabrication to be completed. Welds and sub-assemblies can be updated to highlight manual and automated welds.

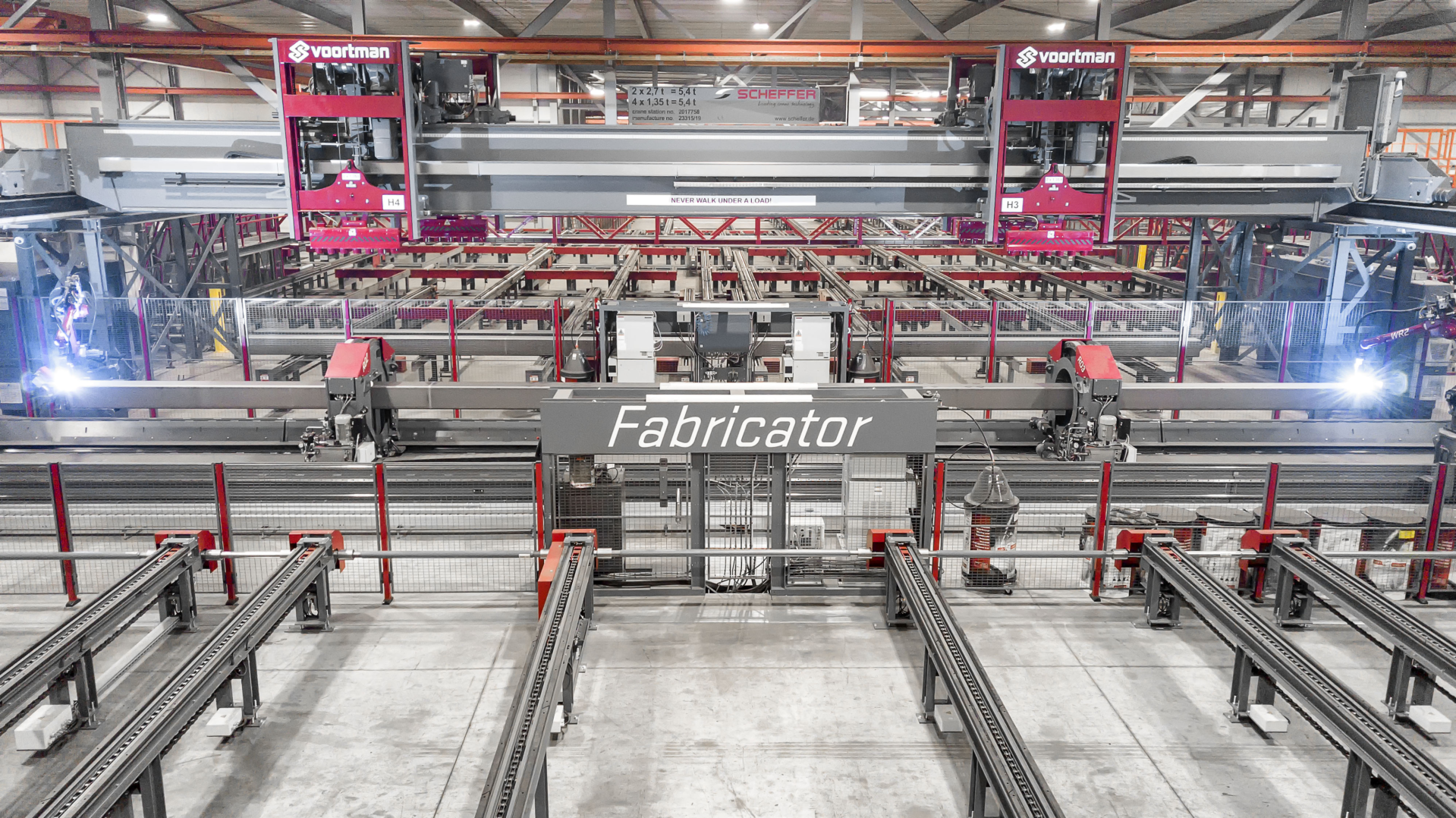

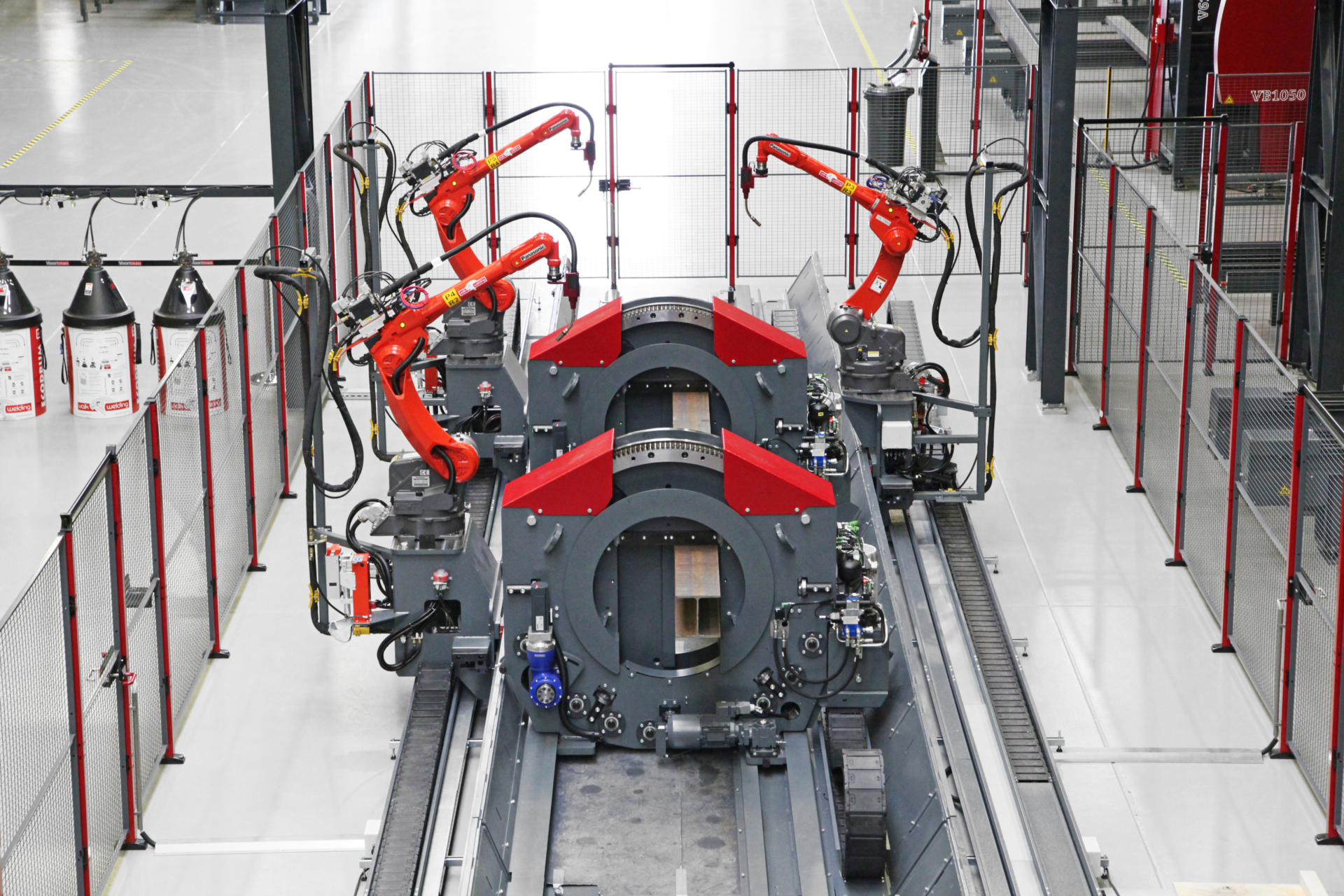

Voortman Integration

Assemblies can be exported to the 'Voortman Fabricator' to allow autonomous production of your fabrications with unrivalled speed and quality.